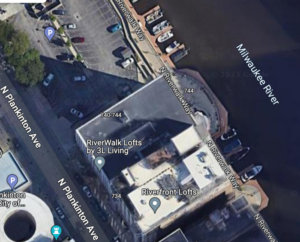

Figure 1

Milwaukee, Wisconsin is home to some of America’s best breweries and one of the finest riverwalks in the nation. The Milwaukee River which is the primary feature of the riverwalk is a 100-mile waterway which is overlooked by many historic buildings in downtown Milwaukee. One of the most iconic is a ten-story condo building known today as Riverfront Lofts which today consists of 36 luxury condos. Designed originally by Armand Koch and built in 1915 as the home of Waldheims Furniture (figure 1), it was repurposed as multi-family housing in the 1990s.

The close proximity to the river provides for spectacular views for the residents of this historic structure, however it has presented challenges over the years when window washing or other exterior maintenance needed to be performed on the eastern exposure of the building due to the extremely limited area to operate a manlift or other ground-based access techniques (Figure 2).

Figure 2

In the hopes of solving this problem once and for all, Riverfront Lofts reached out to Lighthouse Safety in Brookfield, Wisconsin. Lighthouse Safety was able to work with the professional fall protection engineers at EFJ Associates located in Green Bay, WI. It was decided that the safest, most effective way to provide access for workers would be through the utilization of rope access methods following the installation of the Harken R27 long span access rail system.

Harken R27 long space access rail is manufactured in Italy. The system which was released in 2016 and has been installed in a variety of applications including building retrofits, new stadiums, industrial assembly lines and countless other locations. The system consists of ball bearing trolleys that ride an anodized aluminum track and can be positioned anywhere on the span and locked in place if needed. On the installation side, the R27LS represents an even easier installation due to the permissible 3-meter gap between brackets for fall protection and 1.5m for human suspension. It is a gamechanger for fall protection and rope access as it is OSHA compliant and certified to EN 795:2012 type B/D, and allows the worker the ability to access anywhere along the span with redundant anchors that provide quick, safe deployment of a two rope system as required by SPRAT and IRATA. (Fugure 3)

Figure 3

Following the decision to utilize the R27LS rail system to solve the access problem on the eastern elevation of the Riverfront lofts, Lighthouse Safety reached out to Harken Safety and Rescue to purchase the needed rail, fasteners and trolleys. Elevated Safety was then chosen as the installer for the system based on our experience working at height and our familiarity with the Harken rail systems.

Elevated Safety which has offices in Chicago, IL, Denver, CO, Orlando, FL and Paris, France utilized a four person install team from our Chicago location and was supported by Harken Technical Support Specialist Heather Robertson as well as Lighthouse Safety Project Manager, Andres Santos. Elevated Safety installation team members are SPRAT certified rope access technicians who have performed hundreds of hours of work at height and have extensive experience with fall protection use and installation.

Figure 4

Together this team arrived on-site on July 17, 2023 to perform the install. The installation was to be done on the inside of a 24” tall, 12” thick brick parapet wall. This design would make the system invisible from the exterior and would provide easy access for future work as workers could easily clip in to the anchors before transitioning over the parapet to perform work.

Over the course of the next three days the team would layout the rail, drill holes in the concrete block to the dimensions as specified by Harken and the engineers at Fall Protection Professionals. The team then used Hilti HY-270 adhesive in conjunction with sleeve anchors and 3/8” stainless steel threaded rod which was used to secure the rail to the existing brick wall. (See figure 4 and figure 5.)

Figure 5

After the rail was successfully installed and all nuts were torqued to required specifications the team function tested the system to ensure all was operating as planned. (Figure 6 and Figure 7)

Elevated Safety and Harken Safety and Rescue are both proud to have been able to play a role in not only helping to improve safety for those tasked with working on the exterior of Riverfront Lofts but also increasing efficiency for future window cleaning and exterior maintenance of this historic structure. We are thrilled to have once again partnered with our good friends at Lighthouse Safety and EFJ Associates to provide a comprehensive access solution.

Figure 6

Figure 7